Effect of material type, cutout shape and temperature on stress and deformation analyses of thin plates

DOI:

https://doi.org/10.5281/zenodo.7472045Keywords:

Cutouts, Stress, Deformation, Plate, FEMAbstract

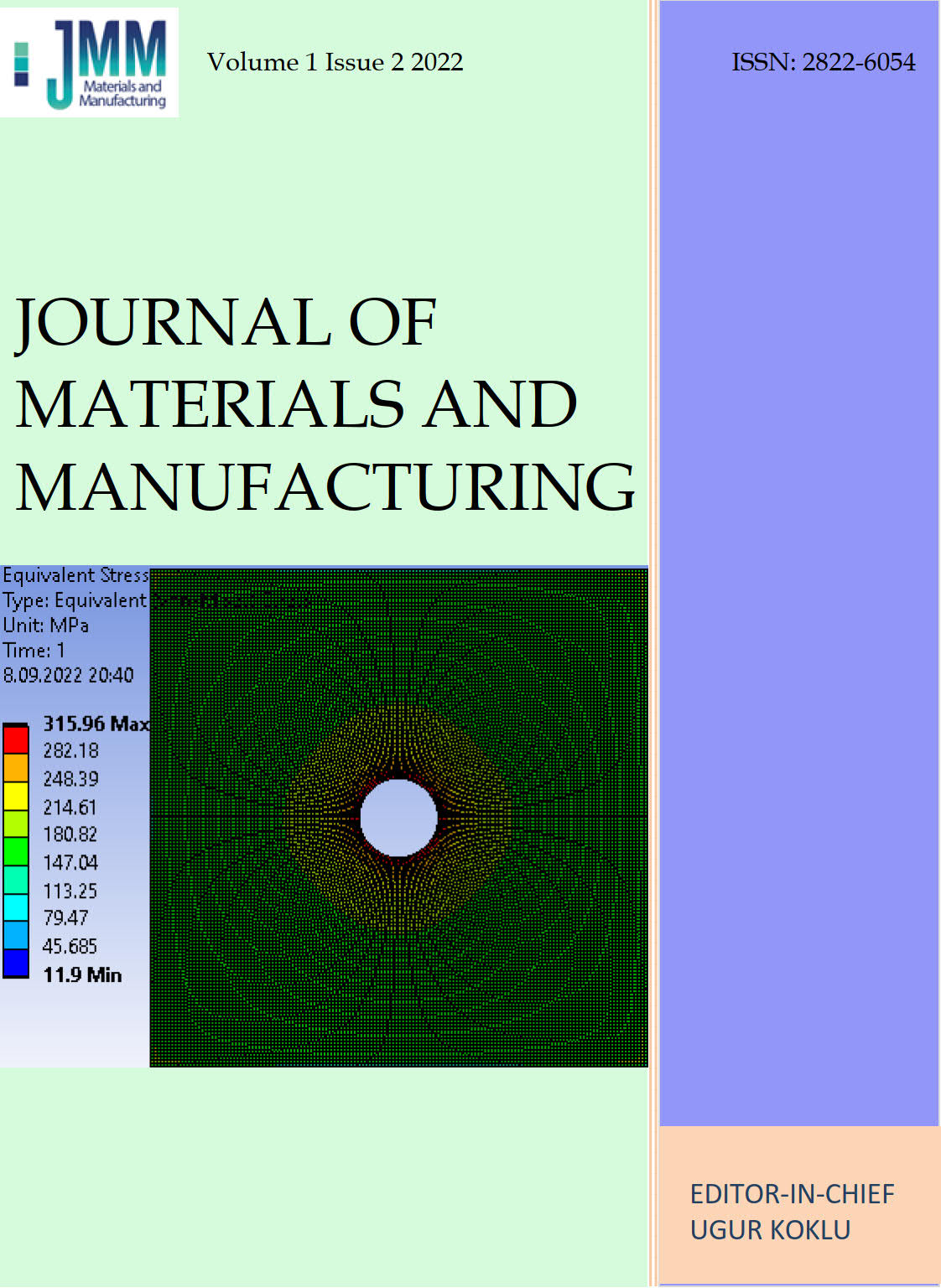

In this numerical and statistical paper, the effect of material type, cutout shape and temperature on von Mises stress and total deformation analysis of plates was examined using numerical and statistical methods. Each plate was analyzed under clamped boundary conditions. The areas of the cutouts were taken equal. Numerical calculations were conducted by Taguchi L8 orthogonal array with three control factors using finite element software ANSYS Workbench. Material type, cutout shape, and temperature of plates were selected as control factors. Effects and the optimum levels of control factors were identified using analysis of signal/noise ratio. Also, meaningful control factors were obtained using analysis of variance. According to results obtained from this study, stress and deformation of plates with cutouts in the form of circular shapes is smaller compared to plates with cutouts in the form of square shapes. Compared to magnesium alloy, aluminum alloy leads to an increase in stress and a decrease in deformation of plates due to temperature increase. In addition, the applied temperature increase provides an increase in the stress and deformation values of the plates. The strongest control factors on stress outcomes are found to be cutout shape with 79.09% effect, temperature with 9.76% effect, and material property with 5.78% effect, respectively. Significant control factors on deformation outputs are obtained as temperature with 56.87% effect, cutout shape with 32.46% effect, and material property with 8.86% effect, respectively. This numerical and statistical study can be used as a reference paper for experimental and numerical studies in the thermal field.